RELATED PRODUCT BRANDS

EXPLORE OTHER PROMACH BUSINESS LINES

EXPLORE OTHER PROMACH BUSINESS LINES

Rigid containers, including bottles, cans, jars, and more, are constantly updated to improve shelf appeal, emphasize new features, highlight nutrition facts, introduce new SKUs, enhance security, and more to win the war for consumer attention. All of these factors impact product labeling needs, and ProMach offers one of the most comprehensive labeling solution portfolios in the industry – from full body sleeves to multi-spot labeling and more – ProMach helps customers maximize the performance of their products on the shelf.

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreHighlights

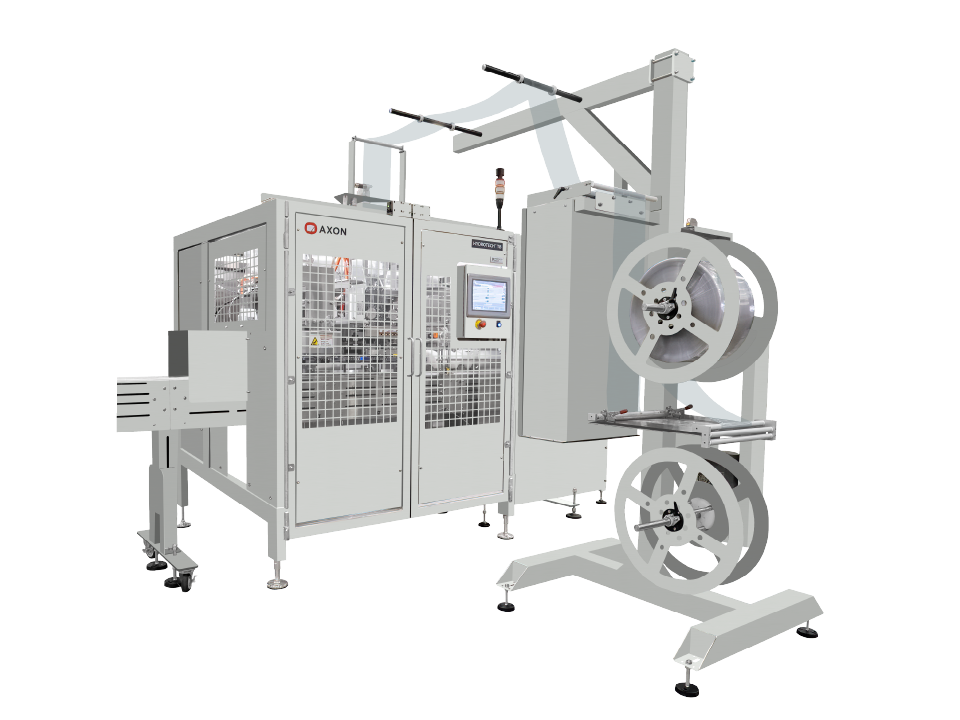

- Quick changeoversRecipe functionality on the touch-screen HMI allow for rapid adjustment of machine settings

- Cutting systemGuillotine knife mechanism provides a clean and precise cut for a high-quality finish - it's also simple to maintain

- EthernetBuilt-in Ethernet/IP communications for rapid line integration and business systems interface

- Small footprintAt 17" wide x 52" deep, an EZ-Series machine conserves valuable floor space

- Bilingual operationEnglish and Spanish HMI for your diverse workforce

- Multiple perforation optionsHorizontal, t-style, or vertical

- PMMI certified trainingOperator training provided by a PMMI Certified Technician

Options

- Static Reduction - Mitigates static build-up and increases uptime

- Print Registration - Fiber optic sensor reads film registration marks so the PLC can calculate cut lengths to assure sleeve length accuracy

- Vertical, Horizontal & T Perforators - Add perforations to enhance ease of opening

- Band Positioning - Belt system assures correct placement of tamper bands or partial body sleeves during the application process

- Low Film Alarm - Automatically detects low film levels and alerts operator

- Product Spacers - Precisely separate containers at the infeed to assure smooth production

- Infeed Timing Screws - Required for multi-packs, certain container geometries

- Spare Parts Kit - Recommended start-up parts inventory