RELATED Decorative Labeling PRODUCT BRANDS

EXPLORE OTHER PROMACH BUSINESS LINES

EXPLORE OTHER PROMACH BUSINESS LINES

Rigid containers, including bottles, cans, jars, and more, are constantly updated to improve shelf appeal, emphasize new features, highlight nutrition facts, introduce new SKUs, enhance security, and more to win the war for consumer attention. All of these factors impact product labeling needs, and ProMach offers one of the most comprehensive labeling solution portfolios in the industry – from full body sleeves to multi-spot labeling and more – ProMach helps customers maximize the performance of their products on the shelf.

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreHighlights

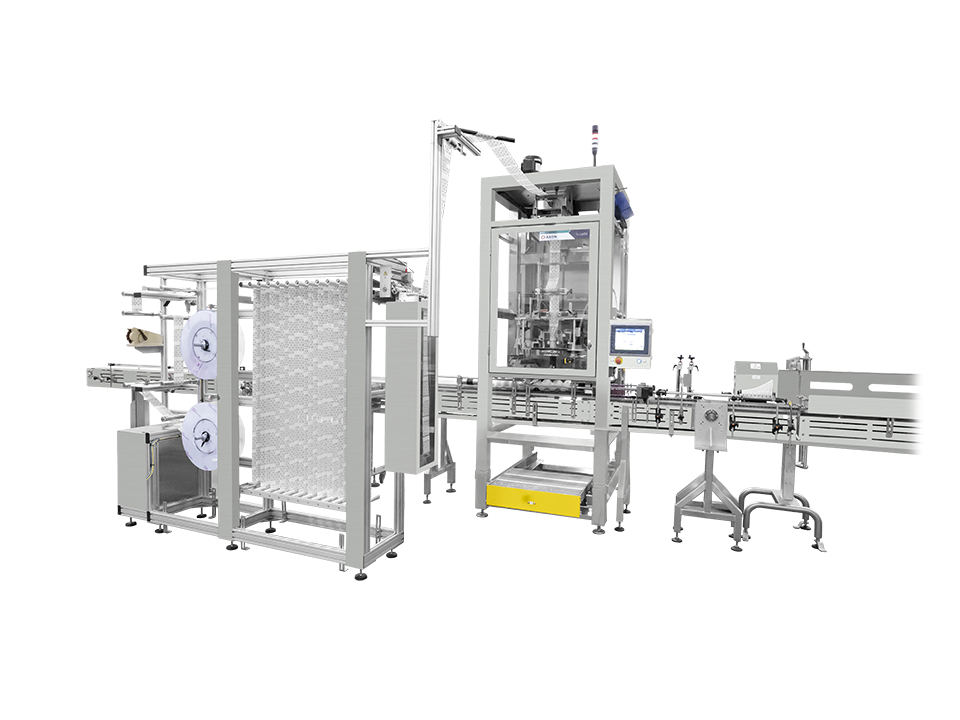

- Horizontal product orientationThe most effective method for handling and sleeving unstable, cylindrical products

- Roller conveyorProvides continuous rotation of product inside the heat tunnel to impart optimal shrink

- Cutting systemGuillotine knife mechanism provides a clean and precise cut for a high-quality finish - it's also simple to maintain

- Recipe functionalityChange machine settings with the push of a button for quick changeovers

- Bilingual operationEnglish, Spanish & Portuguese HMI

- PMMI certified trainingOperator training provided by a PMMI Certified Technician

Options

- Dual Applicator Heads - Second head increases production speeds up to 120 cpm

- Print Registration System - Fiber optic sensor reads film registration marks so the PLC can calculate cut lengths to assure sleeve length accuracy

- Inspection & Rejection - Detects presence or absence of a sleeve (typically prior to shrink tunnel). No sleeve = container rejection

- Vertical, Horizontal & T Perforators - Add perforations to enhance ease of opening

- Non-round product handling - Rotates non-round containers to enhance shrink quality

- Date Code Printers – Integrated thermal transfer printing of UPC codes and date codes

- Infeed Hopper - Allows operators to load product into an automated container feed system that meters and discharges single containers onto the infeed conveyor

- Spare Parts Kit - Recommended start-up parts inventory